Overview

Chimneys are important structures for industrial buildings. With the increasing installed capacity of thermal

power plants in recent years, the design height of chimneys is getting higher and higher due to the

increasingly stringent requirements for environmental protection. As the construction of chimneys is difficult

and risky.

Zolo has developed special slipform equipment for chimney construction to ensure the quality and safety of chimney construction.

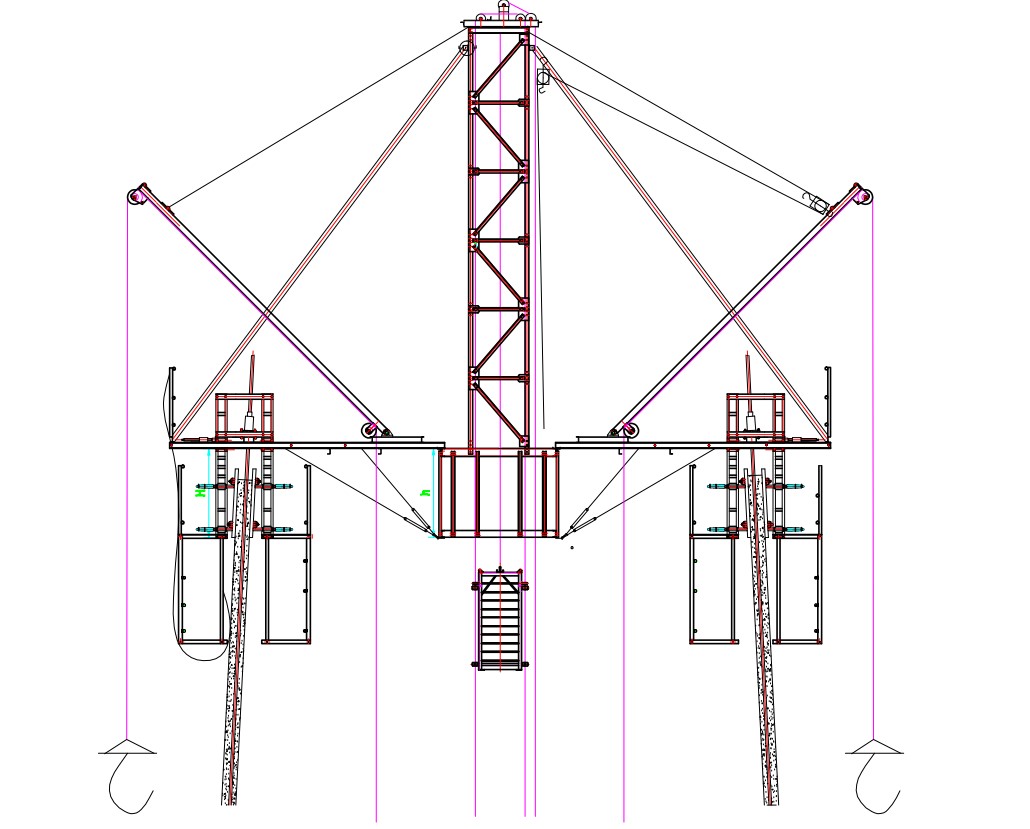

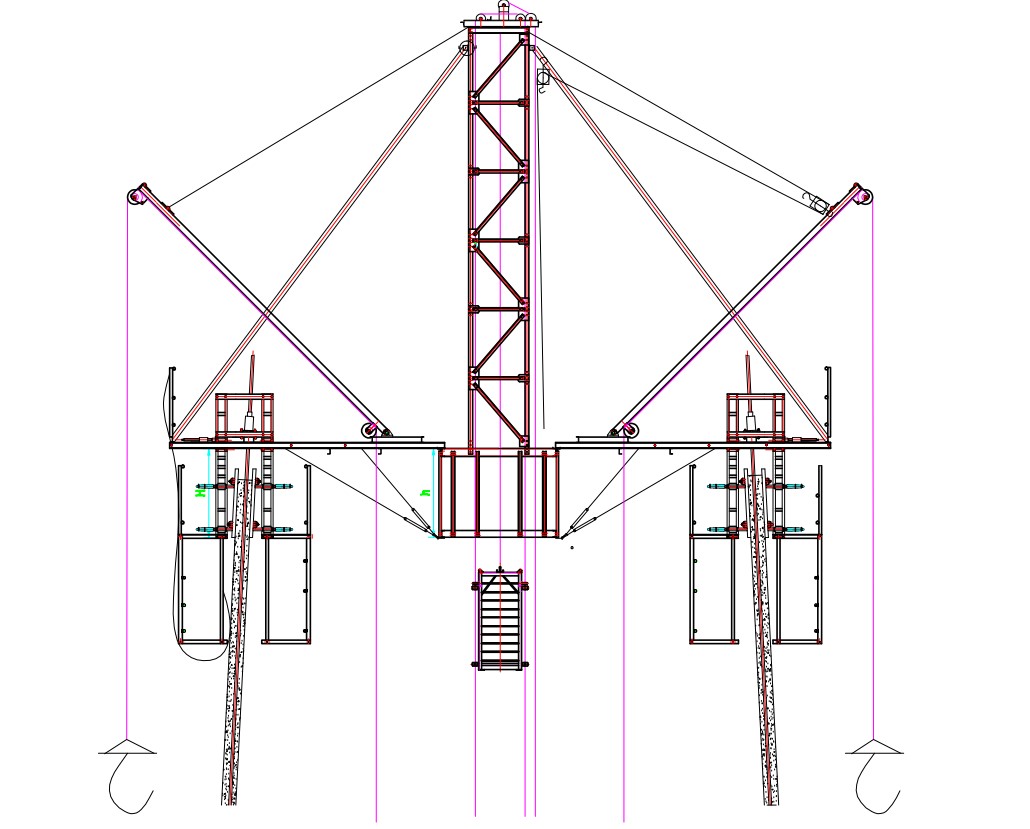

Zolo Chimney Slipform is a sliding formwork with a height of about 1.5m formwork panel assembled at once at

the bottom of the chimney along the inner and outer sides of the cylinder wall, and then the reinforcing bars

are tied and concrete is poured in the formwork in layers continuously.

Through the hydraulic slipform equipment, the formwork is continuously slid upward to complete the pouring of

concrete continuously until the structure is completed.

During the sliding up process, the radius of the formwork is changed by adjusting the adjustable bolts on the

operating platform, in order to meet the requirements of the chimney and other structures to change slopes and

cross-sections.

Features

Compared with other chimney engineering process, Zolo Chimney Slipform has features belowing:

1. Fast construction speed

2. Highly mechanized slipform system

3. Good seismic performance

4. Perfect concrete finish quality & safe operation is guaranteed

5. The slipform system can save the material of formwork and scaffolding , can be more convenient to dismantle